test 4

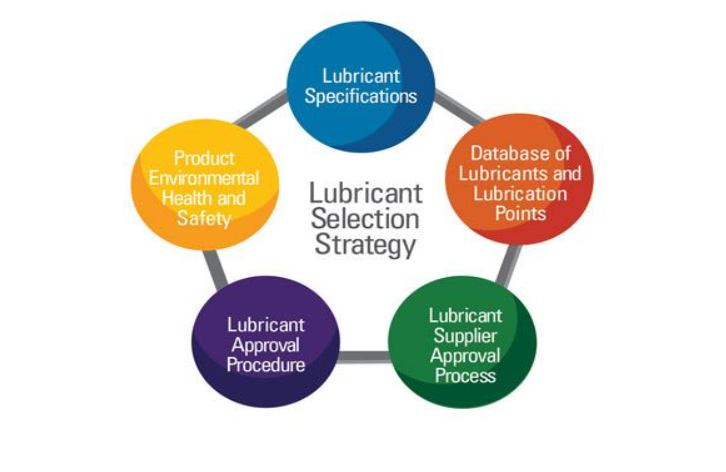

Correct selection of lubricant is essential for the maintaining the long life of machinery/ engine or the equipment. Selection of lubricant is based on the application, service temperature range, speed factor, extreme pressure conditions, acceptable relubrication intervals, cost which indirectly depends on the lubricant specification or technical data. This defines the lubricant’s general function or purpose as well as the material type. It also describes specific applications for which it is required.

To determine which type of lubricant is best for an application, one must understand the current situation. Look at application/environmental factors such as speed, temperature, load, vibration, moisture, and dust. Consider that:

• Temperature determines lubricant base oil type

• Speed determines viscosity required (at operating temperature)

• Load, vibration, and moisture determine the additive package

There are three (3) classifications of a lubricant:

1. Fluid (Liquid)

2. Semi-Solid (Grease)

3. Solids (Dry)

For any application, it is essential to understand lubricants physical, chemical and performance properties in bench or rig tests as well as compatibility of the lubricant product’s with other lubricants as well as with synthetic materials existing in machine lubrication systems, such as seals and gaskets. Compatibility may have added importance when the standard refers to synthetic lubricants or special formulas, since they may require specific procedures when switching to other lubricants. For example, this product is manufactured with polyalkylene glycol (polyglycol) base stock, which is not compatible with mineral oils and other synthetics such as polyalphaolephins.

Some machines or equipment’s may require lubricant approvals or endorsements in which the lubricant product is intended to be used. These approvals may come from original equipment manufacturers (OEMs) or other industry organizations, such as the American Gear Manufacturers Association (AGMA), the National Lubricating Grease Institute (NLGI), etc. Please note that some lubricants may claim a certification or approval for certain technical standards or OEM specifications, while others may only “comply with” the standard or requirement but are not necessarily approved or certified. This may be particularly significant when complying with equipment warranty requirements.

Potential restrictions and hazards describes any undesired ingredients or product properties as well as toxicological or safety aspects to be considered when buying or handling the lubricant. For example, the product must not have mutagenic or carcinogenic compounds.

Lubricants

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

test 4

SGL Chassis Grease is water-resistant calcium soap based grease with a thickening agent. It was specifically developed for central lubrication systems for commercial vehicles. The product contains anti-oxidants, corrosion inhibitors, extreme pressure and anti-wear additives.

| Appearance | Smooth and Homogeneous |

|---|---|

| NLGI Grade | 1 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | Not specified |

| Thickener Type | Calcium |

| Dropping Point | 90 min |

| EP Properties | No |

| Operating Temperature | -10 to 60C |

| Appearance | Smooth and Homogeneous |

| NLGI Grade | 2 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Calcium Sulfonate Complex |

| Dropping Point, oC | 280 min |

| EP & AW Properties | Yes |

| Operating Temperature | -20 to 160C |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Are Lithium Thickener base greases made by using highly refined mineral oils, additives along with solid lubricants They have excellent anti-rust and anti-oxidant properties. Recommended for shock load applications.

| Appearance | Dark Grey ,Smooth and Homogeneous |

| NLGI Grade | 2 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Lithium |

| Dropping Point, oC | 180 min |

| EP Properties | Yes (Contains Moly) |

| Operating Temperature | -20 to 120C |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

| Appearance | Smooth and Homogeneous |

| NLGI Grade | 2 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Calcium Sulfonate Complex |

| Dropping Point, oC | 280 min |

| EP & AW Properties | Yes |

| Operating Temperature | -20 to 160C |

Are Lithium Thickener base greases made by using highly refined heavy mineral oils. The have excellent anti-rust and anti-oxidant properties. Recommended for the lubrication of general purpose applications.

| Appearance | Smooth and Homogeneous |

| NLGI Grade | 3 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Lithium |

| Dropping Point, oC | 180 min |

| EP Properties | No |

| Operating Temperature | -20 to 120C |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

SGL Li EP 2 and Li EP 3 Grease are Lithium Thickener base greases made by using highly refined heavy mineral oils. The have excellent EP, anti-rust and anti-oxidant properties. Recommended for the lubrication of bearings.

| Appearance | Smooth and Homogeneous |

| NLGI Grade | 2 & 3 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Lithium |

| Dropping Point, oC | 180 min |

| EP Properties | Yes |

| Operating Temperature | -20 to 120C |

Are Lithium Thickener base greases made by using highly refined mineral oils, additives along with solid lubricants They have excellent anti-rust and anti-oxidant properties. Recommended for shock load applications.

| Appearance | Dark Grey ,Smooth and Homogeneous |

| NLGI Grade | 2 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Lithium |

| Dropping Point, oC | 180 min |

| EP Properties | Yes (Contains Moly) |

| Operating Temperature | -20 to 120C |

Are basically sodium soap grease:

The demand of soda base greases are getting down slowly. Now a days people are preferring Lithium base greases instead of soda base greases.

Recommended for lubrication of universal joints, wheel bearings, high temperature clutch release, generator and fan bearings.

Physico-chemical properties:

| Appearance | Smooth and Homogeneous |

| NLGI Grade | 2 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | 19 cSt min |

| Thickener Type | Sodium |

| Dropping Point, oC | 180 min |

| EP Properties | Yes |

| Operating Temperature | -10 to 120C |

Pin & Bush grease is well known multi-purpose Lithium grease. The grease allows the presence of very fine grade graphite which will fill surfaces and distribute load evenly preventing further wear and tear. It is suitable for the lubrication of various industrial, agricultural and earth moving equipment applications.

Physico-chemical properties:

| Appearance | Dark Grey ,Smooth and Homogeneous |

| NLGI Grade | 1.5 |

| Base Oil Type | Mineral |

| Base Oil Viscosity | VG 150 |

| Thickener Type | Lithium complex |

| Dropping Point, oC | 220 min |

| EP & AW Properties | Yes |

| Operating Temperature | -20 to 130C |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.

SGL CF-4 ENGINE OIL

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim.