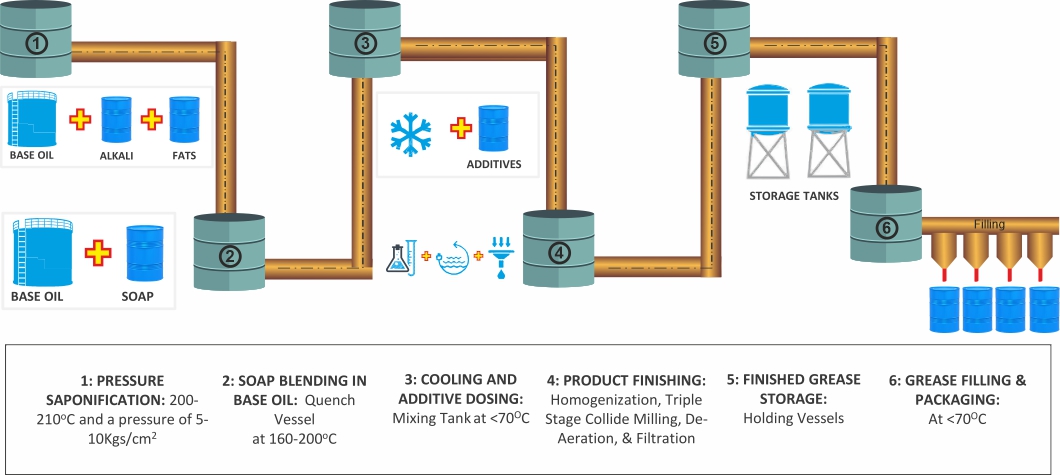

Grease Manufacturing Process

We at TLG, follow a unique 3L Grease manufacturing process, which assures our customers on the Quality of the product supplied by us.

We have state of the art world class manufacturing set-up at our Trinity Plant. The plant is equipped with highly urbane Plant & Machineries such as Pressure Vessel, Unique Open Cooking Kettle, Charlotte Colloid Mill, US Make Grease Filtration system capable to filter the grease in various micron sizes up to 50 micron size particles, Imported High Pressure Homogenizer, Grease De-Aerators and many more. All the valves are automated and are operated thru PLC Room, No manual operation.

The product manufactured by us passes thru various quality checks before it is released for dispatch to our customers. We have multiple product certification teams working in multiple independent Laboratories with dedicated resources.

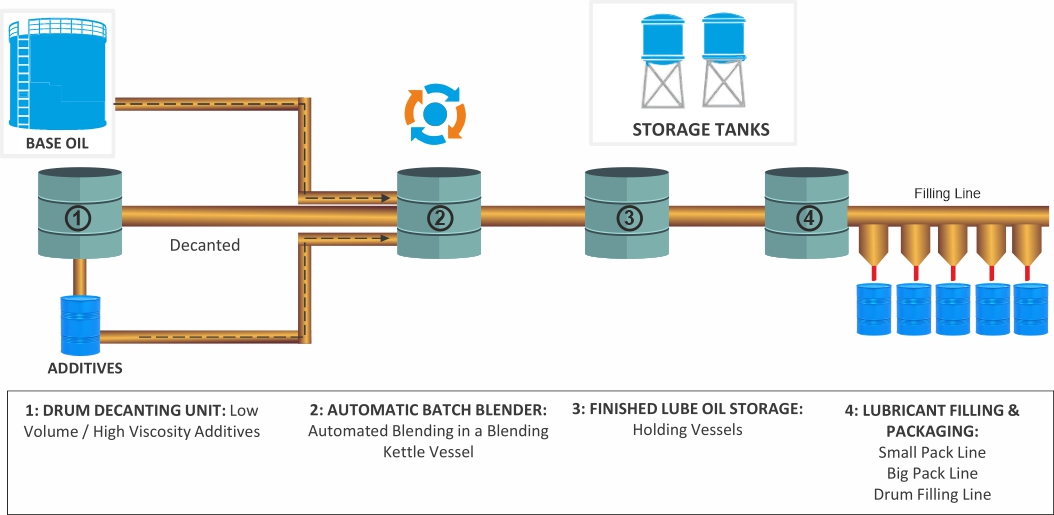

Oil Manufacturing Process

The new Trinity plant at Sharjah is a fully automatic & most modern lubricating blending/manufacturing unit. The plant consists of a fully automatic base oil & additive loading through SCADA system. These helps to load different base oils and additive packages directly from the storage tanks to the blending vessels, almost without human touch. The above help in most accurate loading of raw materials, saving substantial production time & labour.

The oils and additives are blended together in blending vessels under required & elevated temperatures (maintained by automatic thermic fluid heating system) & transferred to holding tanks after necessary quality control checks & approvals. Once approved by QC, materials transferred to filling lines.